Industries

Legacy industrial systems no longer serve the pace or demands of the modern world. Our robots are multi-disciplinary and built to support your workforce on critical operational functions

Maritime

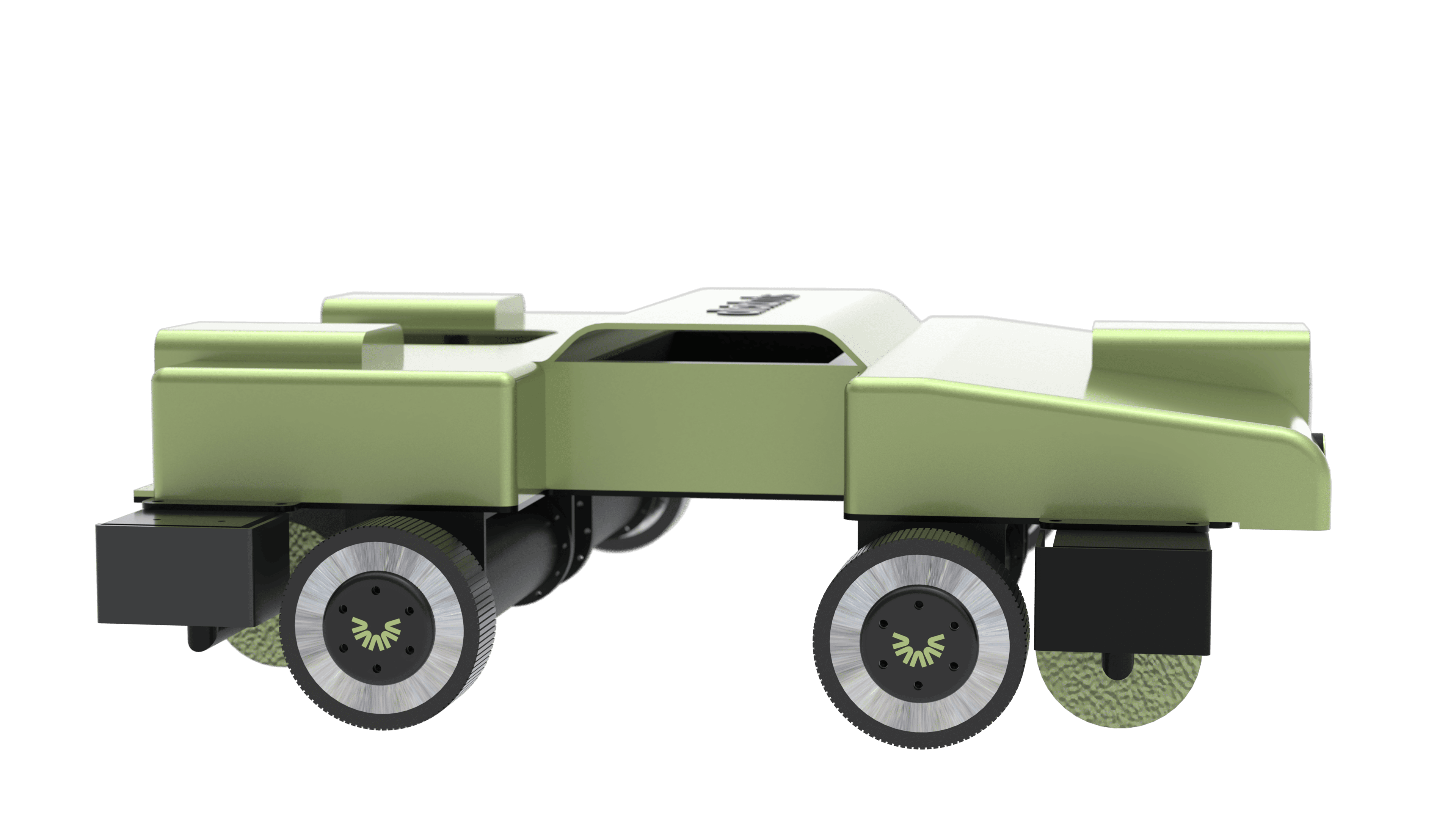

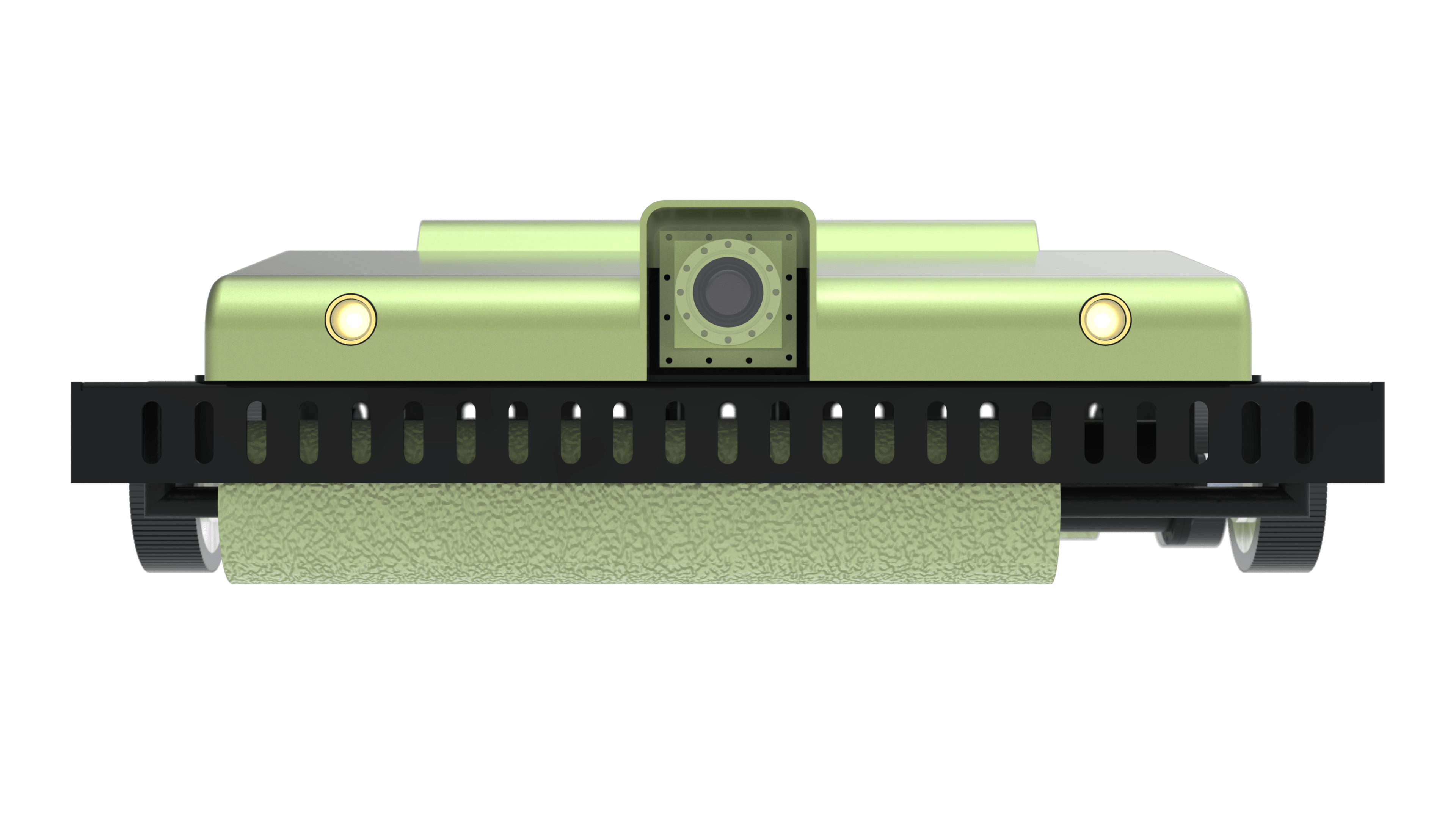

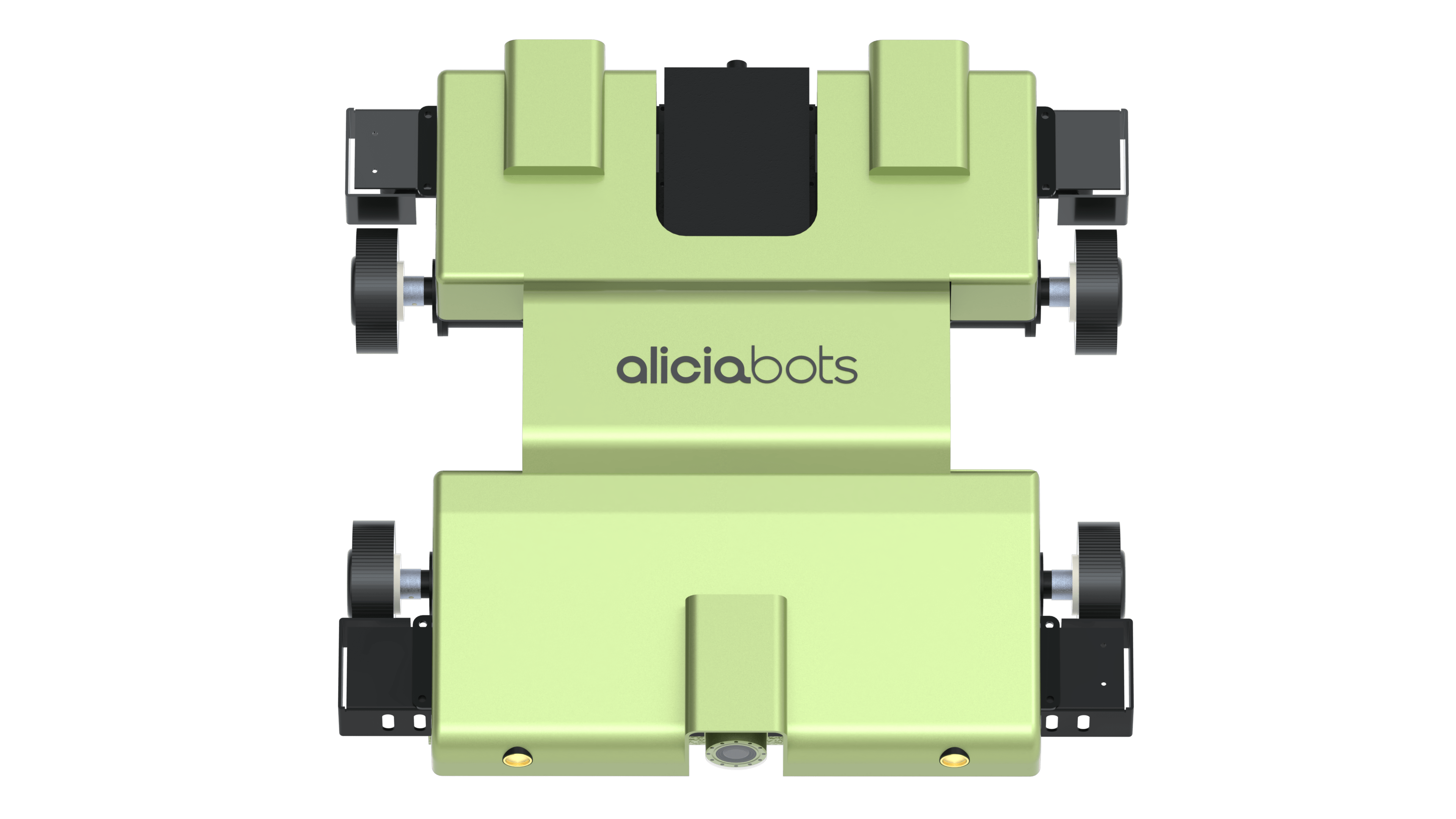

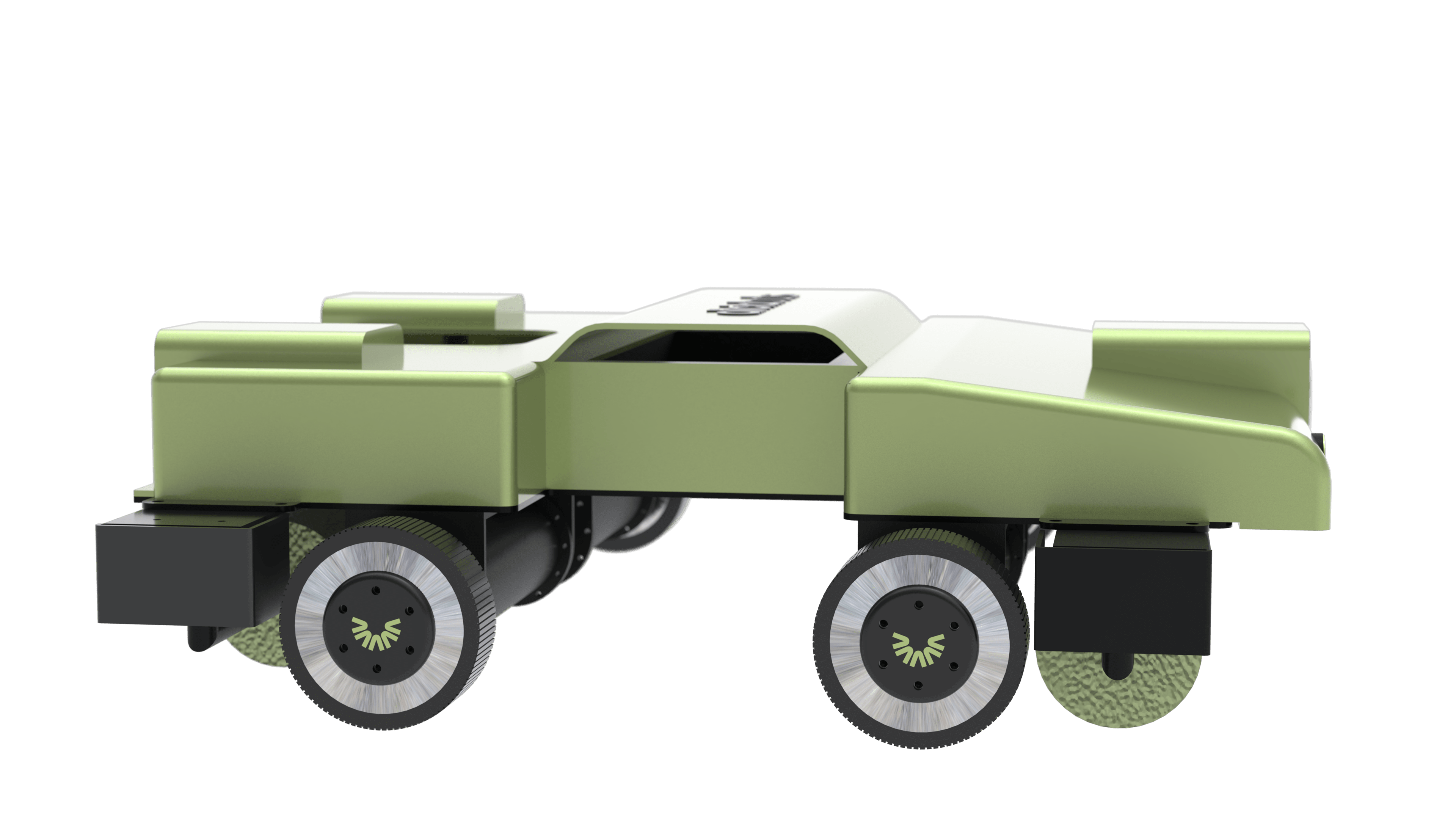

RoverClean transforms hull maintenance from reactive to routine, saving fuel and cutting CO₂.

Oil & gas

Cuts corrosion , robotically grooms and inspects

Offshore

Portable systems yet augmented outcomes.

Why we're different

Efficiency by design

Every system we build eliminates waste and improves performance.

Human + machine collaboration

We enhance crews with intelligent automation, not replacements.

Continuous learning

Our systems evolve with every deployment, always getting smarter.

Real-world impact

We focus on measurable outcomes: fuel savings, emissions reduction, and operational uptime.

Future-ready solutions

Designed to meet today's demands and tomorrow's regulations.

Sustainability

1.

Proactive Biofouling Management to Reduce Emissions

Our Roverclean effectively removes microfouling before it increases hull drag, resulting in fuel savings of 4-5%. This reduction directly lowers CO₂ and greenhouse gas emissions per voyage.

2.

Support for IMO Decarbonisation Goals

By keeping hulls clean, we assist ship operators in improving their Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI) ratings, aligning with international maritime climate targets.

3.

Eliminating Biocide-Based Pollution

Unlike traditional cleaning methods that damage coatings or utilise harmful chemicals, Roverclean employs non-abrasive, biocide-free grooming, minimising harm to marine ecosystems.

4.

No Diver Risk, No Environmental Discharge

Our robotic cleaning process is entirely diver-free and prevents the release of macrofouling or heavy metals into the ocean, ensuring both human safety and water quality.

5.

Circular Design & Minimal Waste

Roverclean is designed for a long service life with replaceable parts and operates with low energy, promoting a low-waste and energy-efficient approach to marine maintenance.

Roadmap

Jan 2020

Project Roverclean initiated

Mar 2021

First deployment of Roverclean 1.0

Tech stars EPS Program

Apr 2022

Company setup in Singapore

MPS research grant

Feb 2023

First commercial deployment with Cargill

Sept 2023

Roverclean 2.0 deployment across Lomar fleet

Dec 2023

Roverclean 3.0 developed with advanced sensor technology

Jan 2024

Total fleet count increased to 28

14 new orders from Hard coatings paint makers.

Nov 2024

Completion of 5 million USD series seed funding round

May 2025

Setup a production facility in Athens, Greece

Oct 2025

First successful remote operation from Athens Workshop